01020304

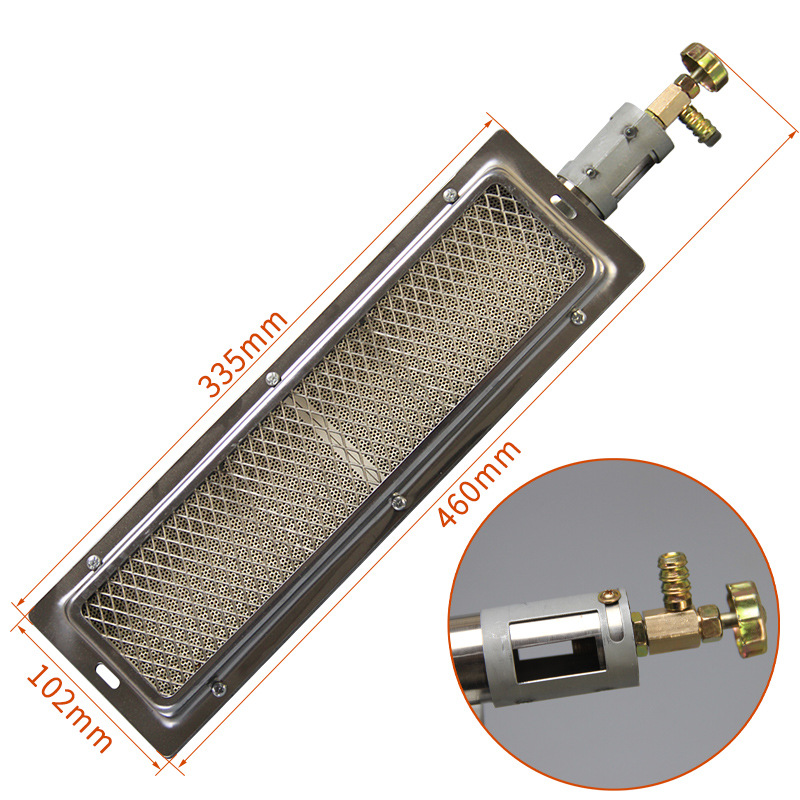

Factory Supply Infrared Ceramic Bbq Gas Burner

description2

description2

Product Description |

Infrared Searing BBQ Burner |

Material |

SS304/SS202/SS430/SS316, Aluminum. |

Product size |

Customized |

Power |

1.8kw-45kw |

Related producdts |

P-shaped burners, U-shaped burners, Cast iron burner, Cast ss304 burners, Infrared burners. |

Food use: Catering use, seafood shop, hand braised chicken, rice crackers, egg rolls, biscuits, dried squid. Fish sauce, dried processed food.

Agricultural processing: Tobacco, tea, grain, aquatic products, vegetables, meat and other products of dehydration, baking.

Food industry: Outdoor oven, lamb string machines, hot cake stove, duck oven, baked sweet potato machine, the drying progress of egg roll, bread, biscuit, dried seasoned squid silk, fish

jam(the food can be heated evenly, no smoke, no pollution, good appearance and good taste)

Paper industry: Drying line of all kinds of papers

Farming industry: Dehydrating and baking of tobacco, tea, corn, aquatic production, and vegetables, meat, etc.

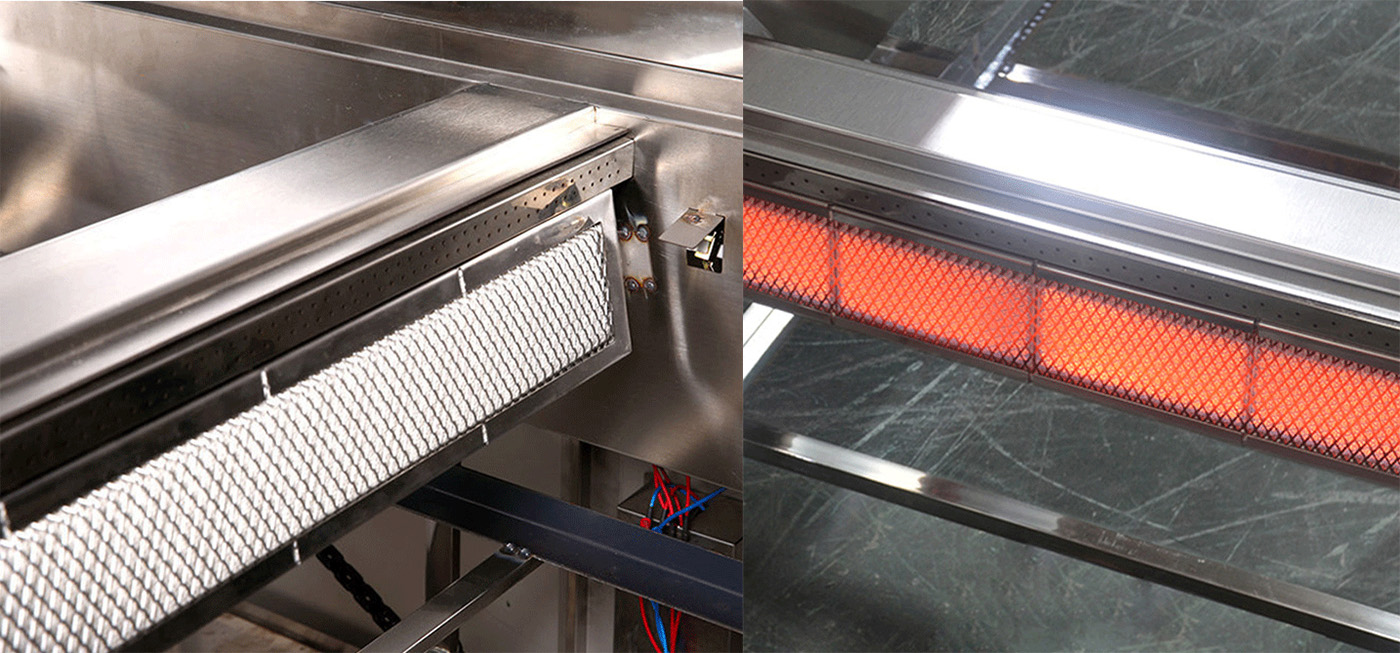

1.Direct heating: not air as the medium, direct infrared radiation to the object in the form of heat transfer. The utility model is a high-efficiency heat source which can carry on the local heating to the essential parts.

2.High Thermal Efficiency: 70% of the heat generated by gas combustion radiates out

in the form of infrared rays, effectively releasing heat.

3. Universal Radiation: infrared burner burning mode for the surface combustion, so in the combustion surface can face up, down, side in any direction.

4.Natural premixed: the unique air/gas mixing device enables the burner to obtain the best gas/air ratio. The whole process is done automatically without human intervention.

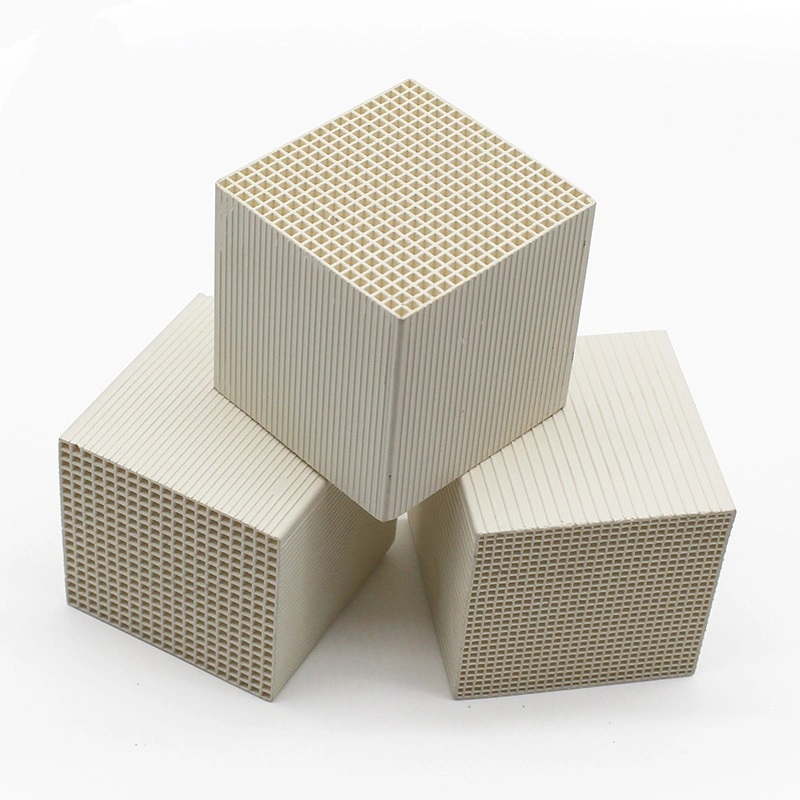

5. Reliable quality: the Regenerator is made of ceramic material with excellent heat resistance and cold resistance, which has good durability and economic benefit The elastic installation technology is adopted to ensure the stable operation of the regenerator. The alloy material has the characteristics of sensitive temperature control reaction, strong temperature resistance, low tempering tendency and long service life.

6. Cost Savings: compared with hot-air cycle, heat exchangers and air ducts are saved; proper piping and installation also lead to a significant reduction in gas consumption; and their life-cycle operating costs are lower than those of hot-air cycle heating.

7.Environmental Protection: because gas almost completely combustion, so no emissions; because no fan, almost silent combustion, so no noise pollution; Therefore, the infrared burner can maximize the protection of the environment.

8. Suitable for baking: the infrared wavelength of the burner is 2-4 μm. This wavelength range of infrared heat is the highest, and particularly easy to be absorbed by water, so it is very suitable for baking, drying items.

We have a variety of customized packaging schemes, and we will choose the appropriate packaging method according to different product volumes, weights, and shapes.