Three-Way Catalytic Converter Ceramic Carrier Honeycomb Dpf

description2

description2

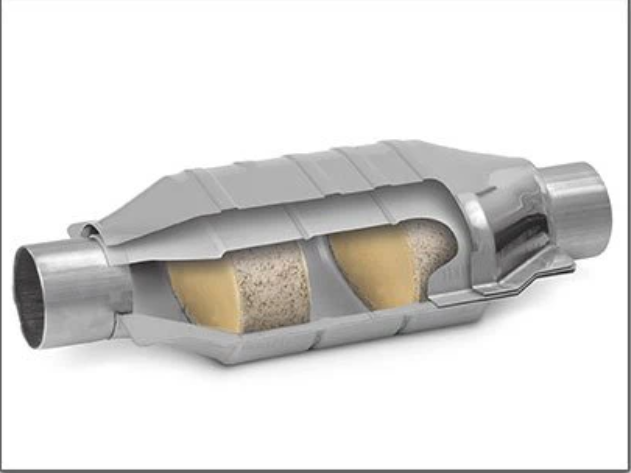

1. The necessary property of honeycomb ceramic catalyst substrate used in cars as follows:1.High specific surface area: ensure exhaust gas could contact weigh catalyst enough.

2.Stable water absorption: guarantee catalyst could be firmly and evenly coated on the surface of substrate, so it's no waste for too thick coating.

3.Warm up characters: after starting up engine, the temperature of substrate could reach the active temperature of catalyst in the shortest time.

4.Low exhaust resistance: ask exhaust resistance of substrate to engine low, so that it won’t affect the performance of engine.

5.High intensity: substrates work in bumpy cars, so the intensity of substrates must be too high to be destroyed.

6.Perfect assembly: substrates are parts of exhaust; perfect appearance and exact dimension could ensure assembly perfect.

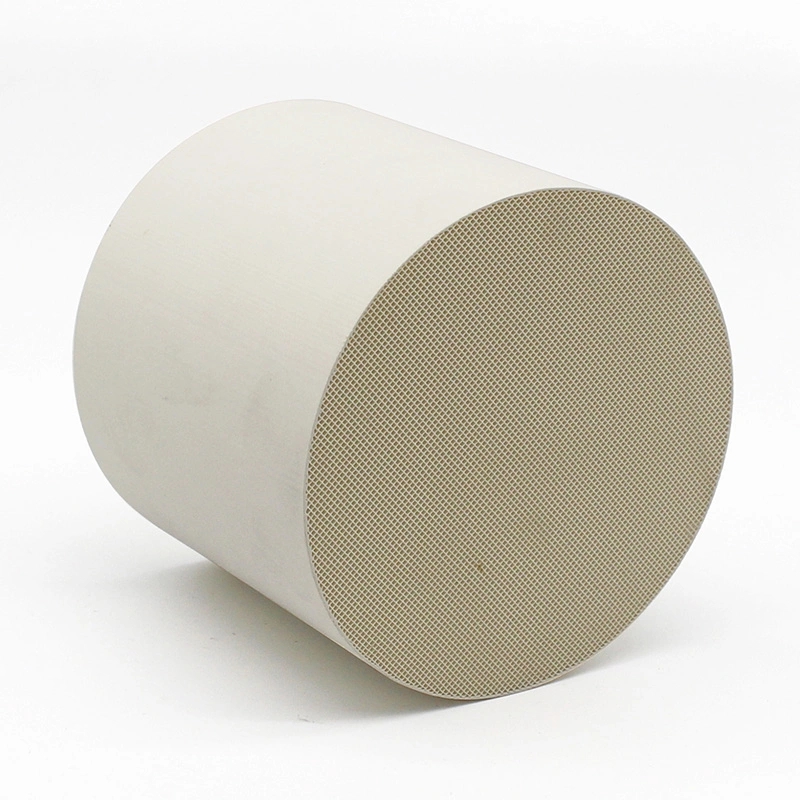

Ceramic honeycomb substrate is a new kind of catalyst monolith, which is widely used in automobile emissions purifying system and industrial exhaust gas treatment system. After coated with catalysts, this product is applied in catalytic converter of diesel or gasoline vehicle to catalyze, convert and purify the exhaust, making vehicle exhaust reaching standards of Euro IV and Euro V.

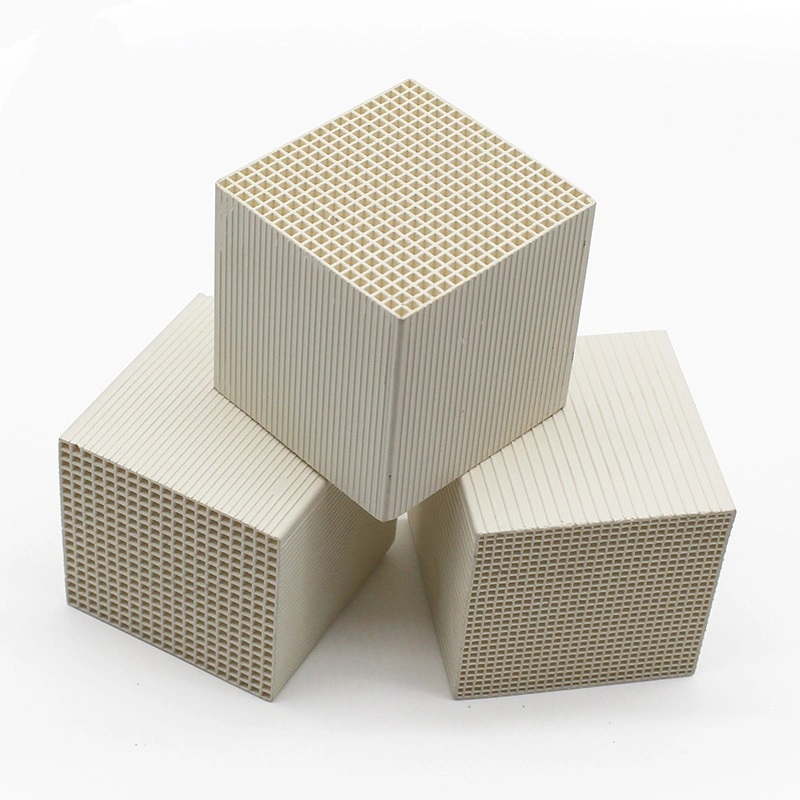

Honeycomb Ceramic (Used In Vehicle)

The ceramic substrate is made of cordierite, and it is used for car catalytic converter. We can supply both ceramic element coated with noble metals of Pt, Pd, Rh and ceramic element without noble metals.

1). The honeycomb ceramic substrate have a very competive substrates.

2). We can produce 100CPSI, 200CPSI,400CPSI,600CPSI can be in the shape of round ,racetrack and ovral.

3).Specification can be customerlized, as the the customers requirement.

4).can be coated with the catalyst and the noble metal as the customers emission standards:Euro II, Euro III and Euro IV and EPA standard and the Cariforlia standards.