0102030405

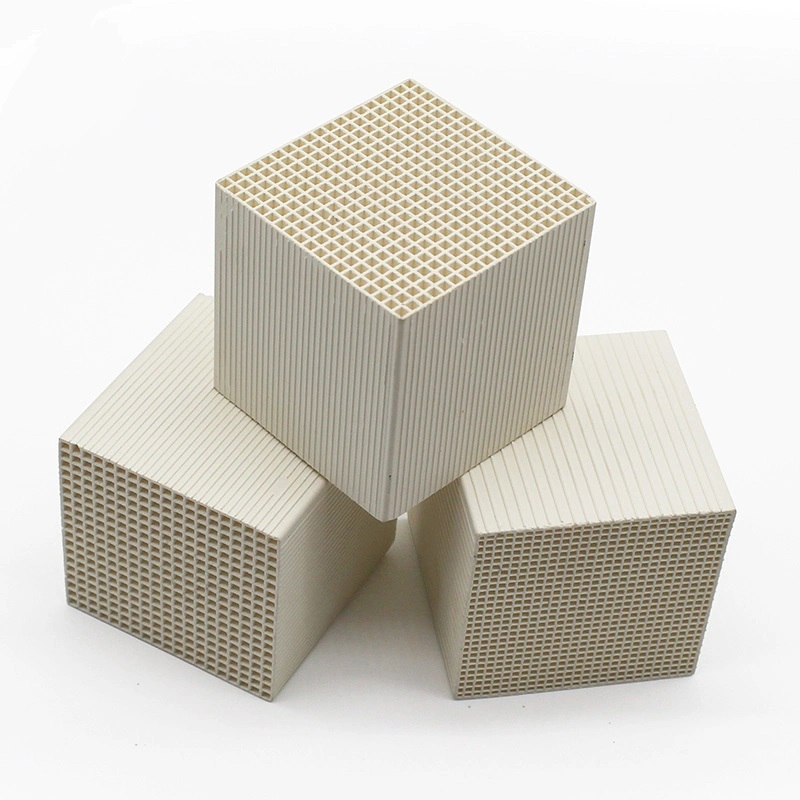

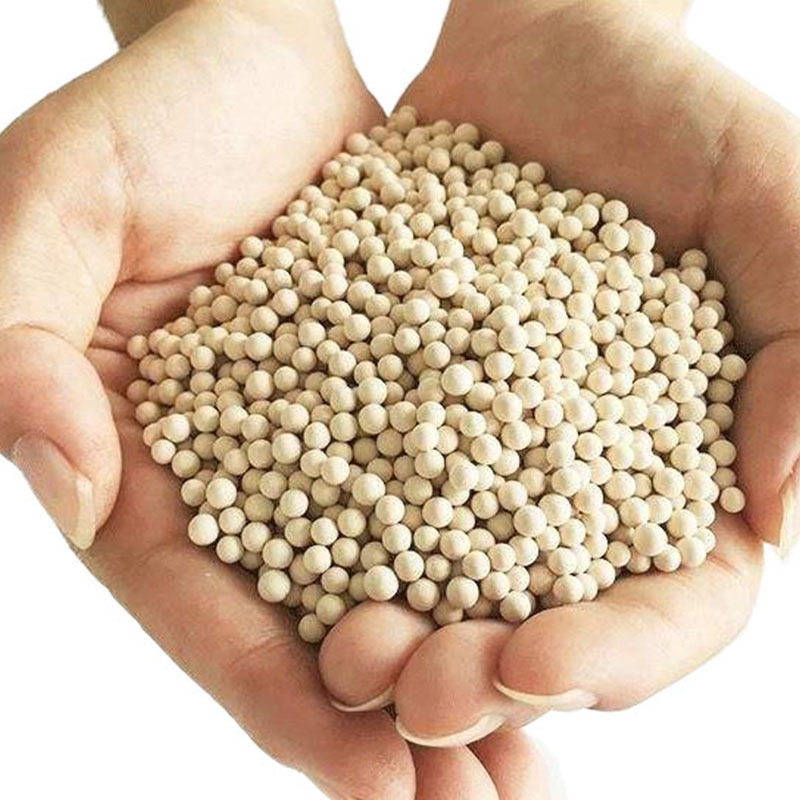

Factory Supply Zeolite 3A/4A/5A/13X Molecular Sieve

description2

description2

Type |

Bulk density ypg/ml |

Water absorption (%) |

Wear ability (%) |

H,O content (%) |

3A |

0.60-0.68 |

19-20 |

0.3-0.6 |

≤1.5 |

4A |

0.60-0.65 |

20-21 |

0.3-0.6 |

≤1.5 |

5A |

0.60-0.65 |

20-21 |

0.3-0.5 |

≤1.5 |

13X |

0.55-0.65 |

23-24 |

0.3-0.5 |

≤1.5 |

1.Large water adsorption:The wel-proportioned apertureand well-arranged cavity in structur emake its large water adsorption.

2.Fast Drying:Uniform aperture distribution,so it can be fast drying.

3.long service life:Regenerating by high temperatureor high pressure, it can be re-used fora long time.

4.Uniform in size:The granules are uniform size.

5.High Hardness:The raw material is zeolite,so it is too hard to break

Oil & Gas applications - Natural Gas processing / Petrochemistry, refining and chemical industries.

Industrial gases applications - Air separation and air purification units / H2 production units / O2 production units / N2 production units.

Static drying- applications - Double pane insulated windows / Coatings, adhesives, sealants and elastomer (Poly Urethane industries).

Individually packaged desiccant - Pharmaceutical packaging / Food applications.

3A Molecular Sieve

1. Mainly used in the drying of unsaturated hydrocarbons such as ethylene, propylene, butadiene, etc. of petroleum cracking gas.

2. Drying of polar liquids such as methanol and ethanol.

3. Air drying.

4. Drying of natural gas and methane gas.

1. Deep drying of gases and liquids such as air, Product namenatural gas, alkanes, and refrigerants.

2. Static drying of pharmaceutical packaging;electronic components and perishable objects.

3. Preparation and purification of argon.

4. Used as a dehydrating agent in paints, fuels and coatings.

1. Pressure swing adsorption devices for various sizes of oxygen, hydrogen, carbon dioxide and other gases.

2. Separation of normal and isoparaffins.

3. Air purification, dehydration and carbon dioxide removal.

4. Drying, dehydration and desulfurization of natural gas.

1. Deep drying of general industrial gases. Purification of raw gas in the air separation Unit (removal of H20, C02 and some hydrocarbons at the same time).

2. Drying and desulfurization of natural gas,liquefied petroleum gas and liquid hydrocarbons.

3. Oxygen production.

1.Round type Super sack(1000*1000*1000 mm) on Fumigation Pallet.20 super sacks is equal to one 20 GP container loading quantity.

2. 100L Plastic Woven bag 10 bags is equal to one cubic meter

3. Cartons on Fumigation pallet 8 cartons is equal to one cubic meter

If you have any other requirement, do it on your requirement.