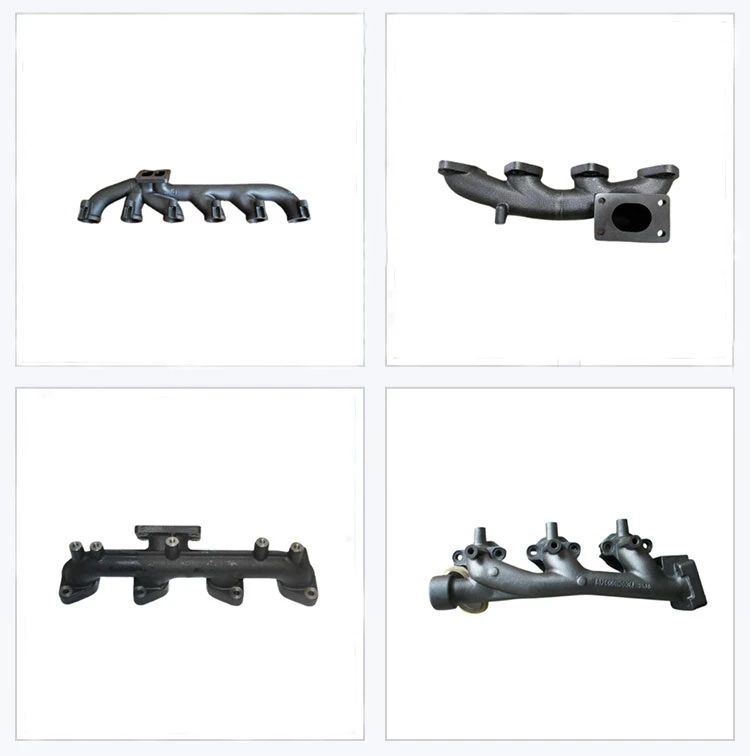

ISO9001 Chaw tsim tshuaj paus Custom Cast Iron Turbo Exhaust Manifold

piav 2

piav 2

① Zoo oxidation tsis kam ntawm qhov kub siab: Ntxiv cov ntsiab lus alloying rau cov khoom siv: Cov khoom siv los tiv thaiv oxidation ntawm qhov kub siab ncaj qha cuam tshuam rau lub neej kev pab cuam ntawm lub tso pa tawm manifold. Ordinary cam khwb cia hlau pom tseeb tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua, yog li ntxiv cov ntsiab lus alloy hauv cov khoom los txhim kho qhov kub-kub oxidation tsis kam ntawm cov khoom.

②Stable microstructure: Cov khoom siv matrix yog qhov zoo dua qhov ruaj khov ferrite lossis austenite qauv.

③ Kub kub thiab corrosion kuj: Me me coefficient ntawm thermal expansion yog qhov zoo los txo cov thermal kev nyuaj siab thiab deformation ntawm pa manifolds thiab txhim kho cov khoom ua tau zoo thiab kev pab cuam lub neej.

④ Cov txheej txheem kev ua tau zoo: Muaj ntau ntau yam ntawm cov khoom siv hluav taws xob thiab kub-resistant hlau, tab sis vim yog cov duab ntawm cov khoom siv hluav taws xob, cov khoom siv los tsim cov pa hluav taws xob yuav tsum muaj kev ua haujlwm zoo.

1.Material: Cam khwb cia hlau los yog 201ss stainless hlau

2.Service: Sand casting, Lub ntiajteb txawj nqus casting, siab siab tuag casting, tsis tshua muaj siab tuag casting thiab CNC Machining casting.

3. Cov cuab yeej ntawm Casting: Xuab zeb casting tshuab; degassing cov cuab yeej thiab cov hauv kev los kho cov khoom siv; 5sets CNC Machinery; 3 teeb Milling tshuab; 3 teeb tig tshuab; 10 teeb laum thiab kais tshuab.

4.Testing facility:spectrometer, tensile test machine, hardness test machine, CMM dimension report.

5.Precision machining: CNC tig, milling, drilling, sib tsoo, txiav, reaming thiab threading.

6.Finished: Polishing, xuab zeb blasting, kho cua sov, painting, hmoov txheej, anodizing, electroplating, Chrome plating, daim iav polishing.

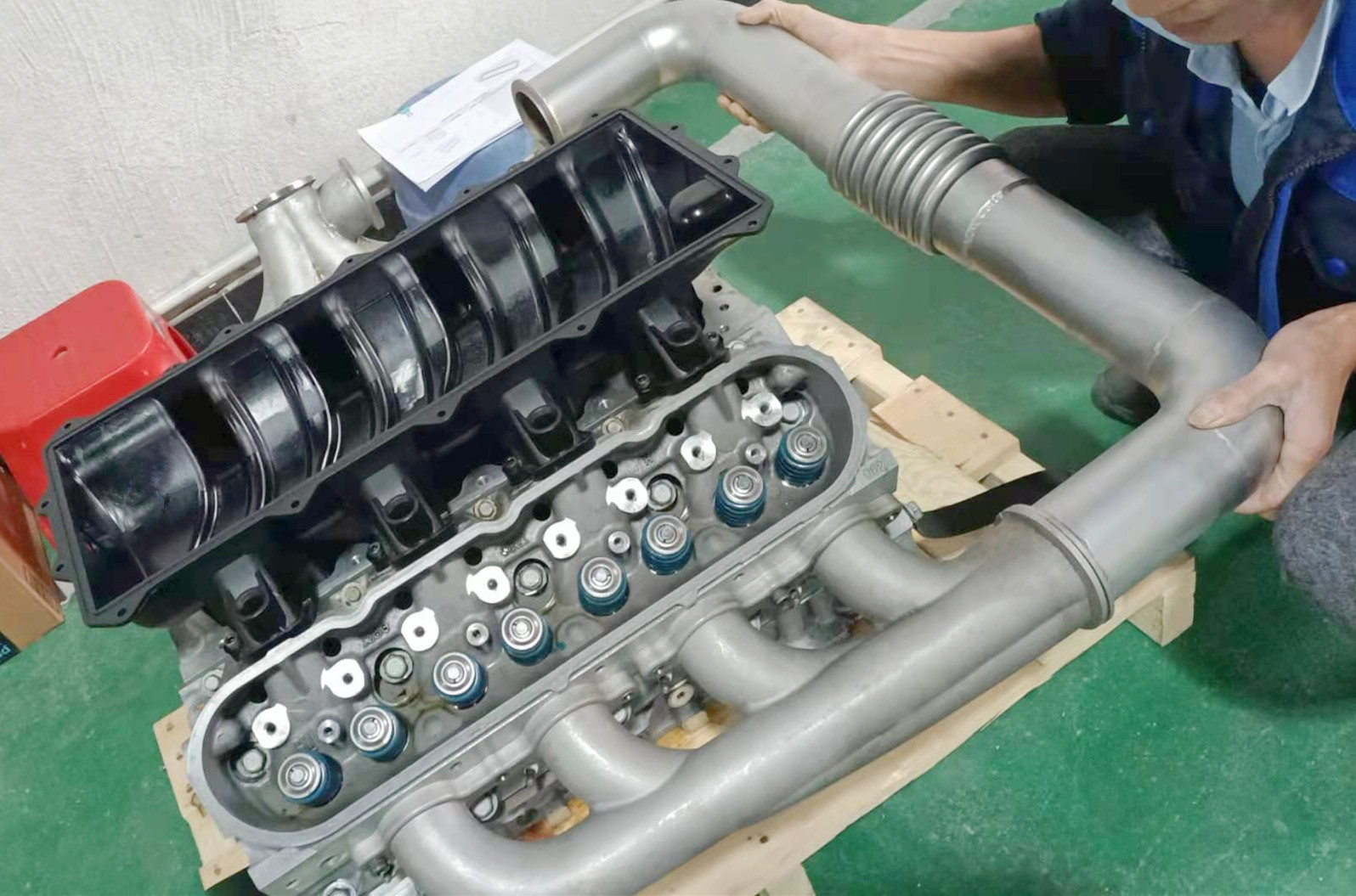

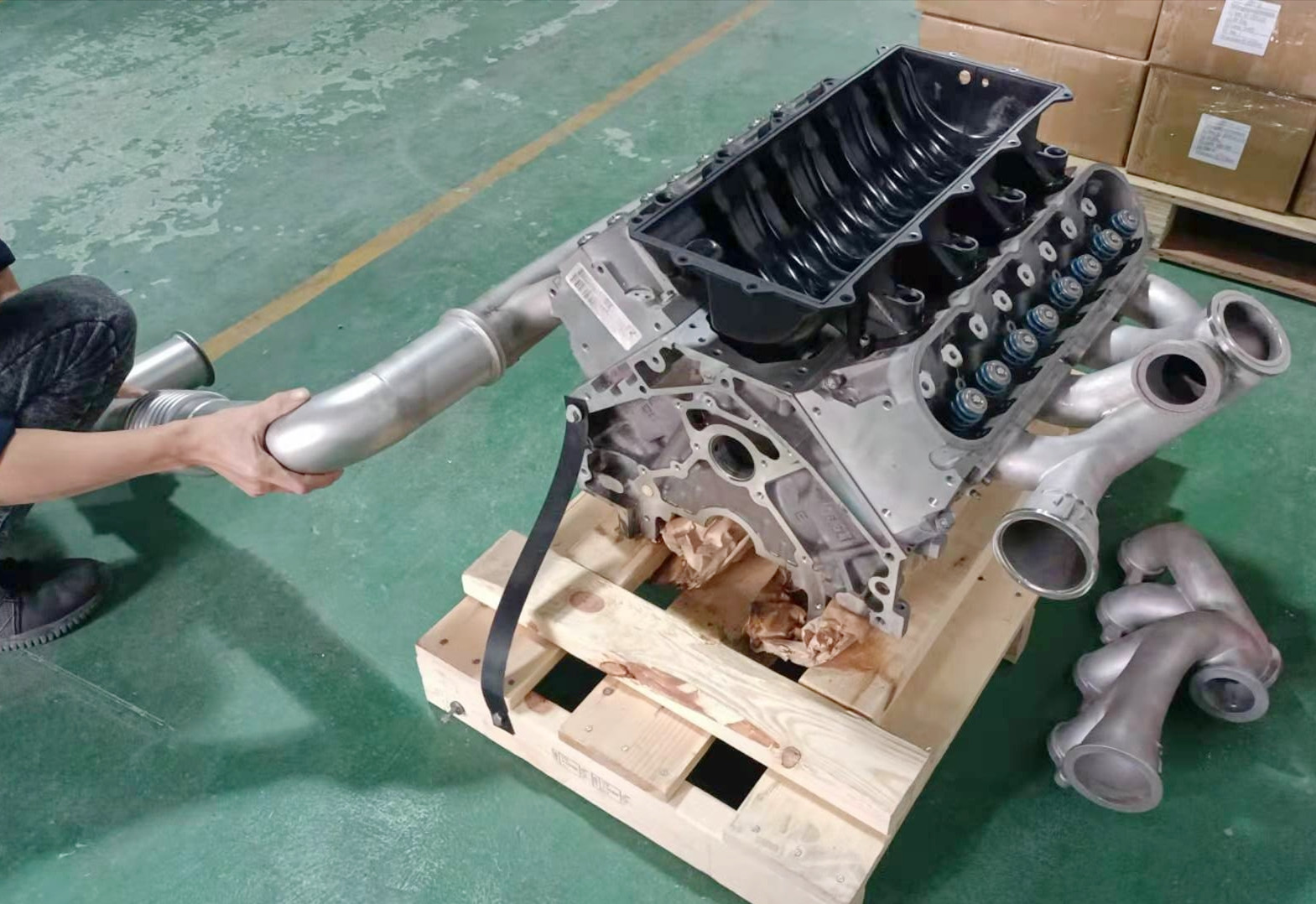

1.Ua kom paub tseeb tias cov qauv tso tawm manifold phim lub tsheb.

2. Nqa lub tsheb kom tau txais kev nkag tau zoo dua rau hauv qab qhov tso pa tawm. Tshem tawm cov pa hluav taws xob uas twb muaj lawm uas siv lub ciaj ntswj.

3.Txhawm rau hauv qab ntawm qhov tso pa tawm. Tshem tawm cov khoom qub tso tawm, hauv qab ntawm qhov tso pa tawm yuav muaj qhov seem lossis xeb, yuav tsum tau ntxuav nrog xab npum lossis hlau txhuam cov cuab yeej.

4.Nruab tshiab tso pa tawm manifold. Muab qhov tso tawm tshiab tso rau ntawm qhov kev sib txuas uas twb muaj lawm thiab ruaj ntseg nrog lub ciaj ntswj. Nws yuav tsum tau muab sau tseg tias cov kev taw qhia ntawm lub tso pa manifold yuav tsum tau them sai sai mus rau lub sij hawm installation los xyuas kom meej tias cov kev taw qhia ntawm airflow yog lawm.

5.Txuas lub tso pa tawm mus rau hauv qab qhov tso pa tawm. Siv tus ciaj ntswj los txuas lub tso pa tawm mus rau hauv qab qhov tso pa tawm thiab xyuas kom tsis muaj cua nkag ntawm kev sib txuas.

6.Kuaj xyuas lub installation ntawm lub tso pa tawm. Tom qab kev teeb tsa yuav tsum xyuas seb qhov tso pa tawm puas yog cov khoom, seb puas muaj cov xau. Yog tias pom muaj qhov xau, nws yuav tsum tau kho lub sijhawm.

Tsev

Tsev