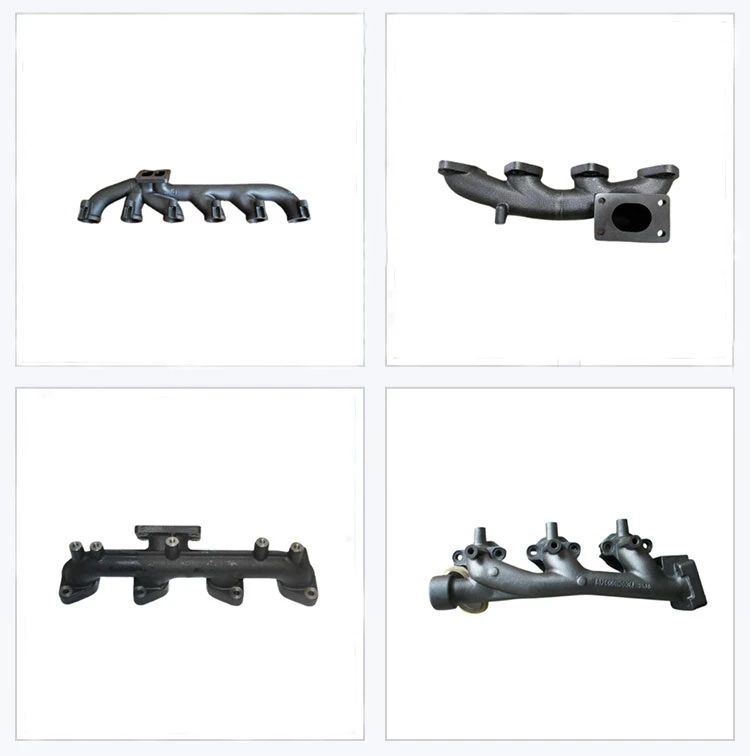

Soo saaraha ISO9001 Cast Iron Turbo Exhaust Manifold

sharaxaad2

sharaxaad2

① Iska caabbinta oksaydhka wanaagsan ee heerkulka sare: Ku darista walxaha alloying ee walxaha: Waxqabadka anti-oxidation ee walxaha heerkulka sare wuxuu si toos ah u saameeyaa nolosha adeegga ee noocyada kala duwan ee qiiqa. Kabka caadiga ah sida cad ma buuxin karo shuruudaha, sidaas darteed ku darida walxaha alloy ee walxaha si loo hagaajiyo caabbinta oksaydhka heerkulka sare ee alaabta.

②Stable microstructure: Qalabka matrixka ayaa doorbidaya qaab dhismeedka ferrite ama austenite deggan.

③ Heerkulka sare iyo iska caabinta daxalka: Isku-xidhka yar ee fidinta kulaylka ayaa faa'iido u leh yaraynta diiqada kulaylka iyo qallafsanaanta qaybaha qiiqa iyo hagaajinta waxqabadka alaabta iyo nolosha adeegga.

④ Waxqabadka habka wanaagsan: Waxaa jira noocyo badan oo ka mid ah qalabka birta ah ee kulaylka u adkaysta iyo heerkulka sare ee u adkaysta, laakiin sababtoo ah qaabka qallafsan ee mashiinnada qiiqa, alaabta loo isticmaalo in lagu soo saaro mashiinnada qiiqa waa inay lahaadaan shaqo fiican.

1.Material:Cast birta ama 201ss ahama

2.Service: Bacaad tuurista, Cufis-jiidad tuurista, Cadaadis sare oo dhinta shubista, Cadaadis yar oo dhinta shubista iyo CNC Machining casting.

3.Qalabka tuurista:Mashiinka tuurista ciid;qalabka dajinta iyo fursadaha lagu sifaynayo walxaha 3 mashiinnada leexinta; 10 mashiinada daloolista iyo tuubada.

Xarunta 4.Tijaabada: spectrometer, mashiinka tijaabada xajinta, mashiinka tijaabada adag, warbixinta cabbirka CMM.

5.Precision machining: CNC jeestay, shiidan, qodista, shiidi, goynta, reaming iyo dunta.

6.Finished: polishing, ciid qarxinta, daaweynta kulaylka, rinjiyeynta, daahan budada, anodizing, koronto, dahaadhay Chrome, dhalaalaysa muraayadda.

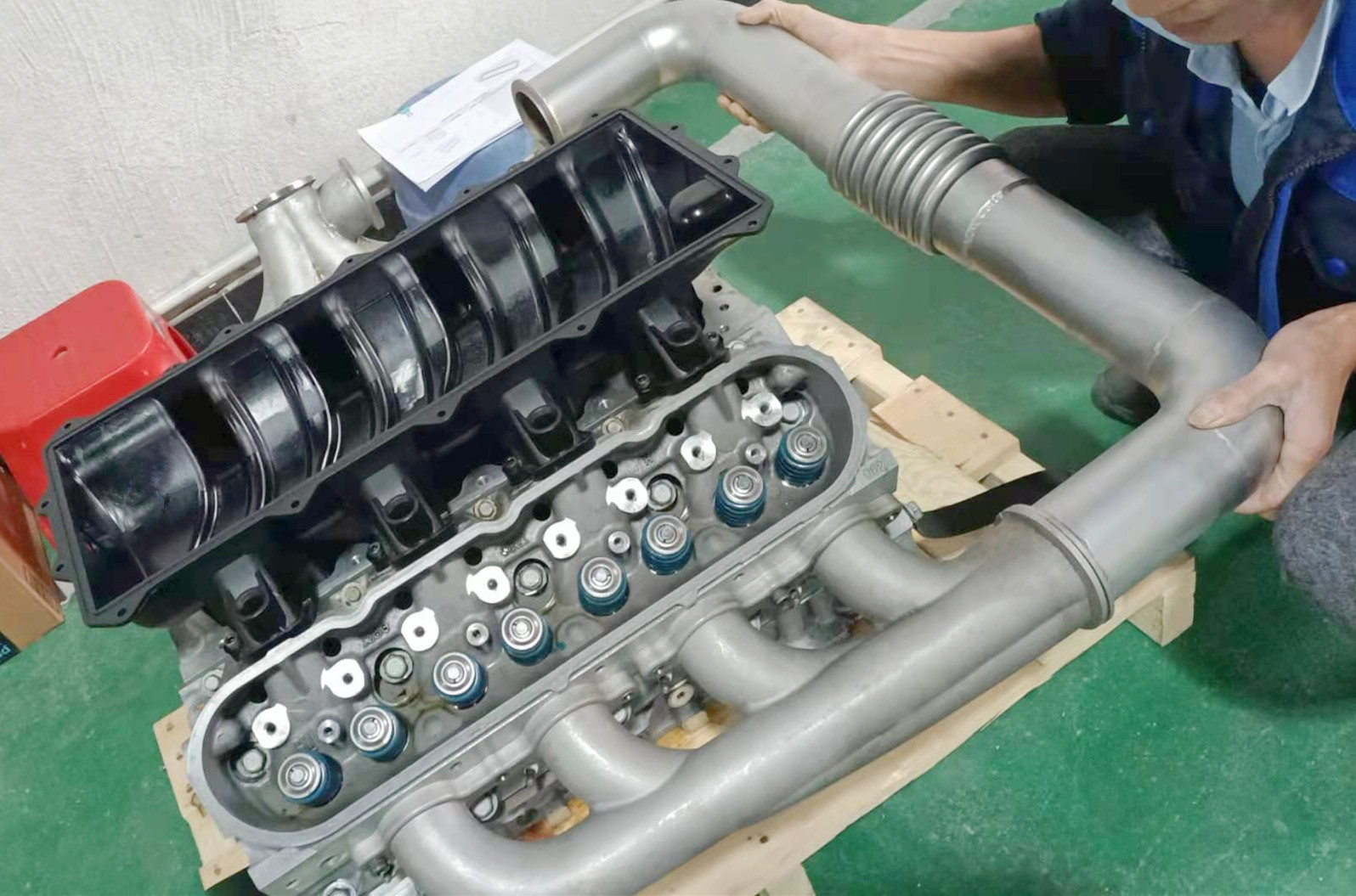

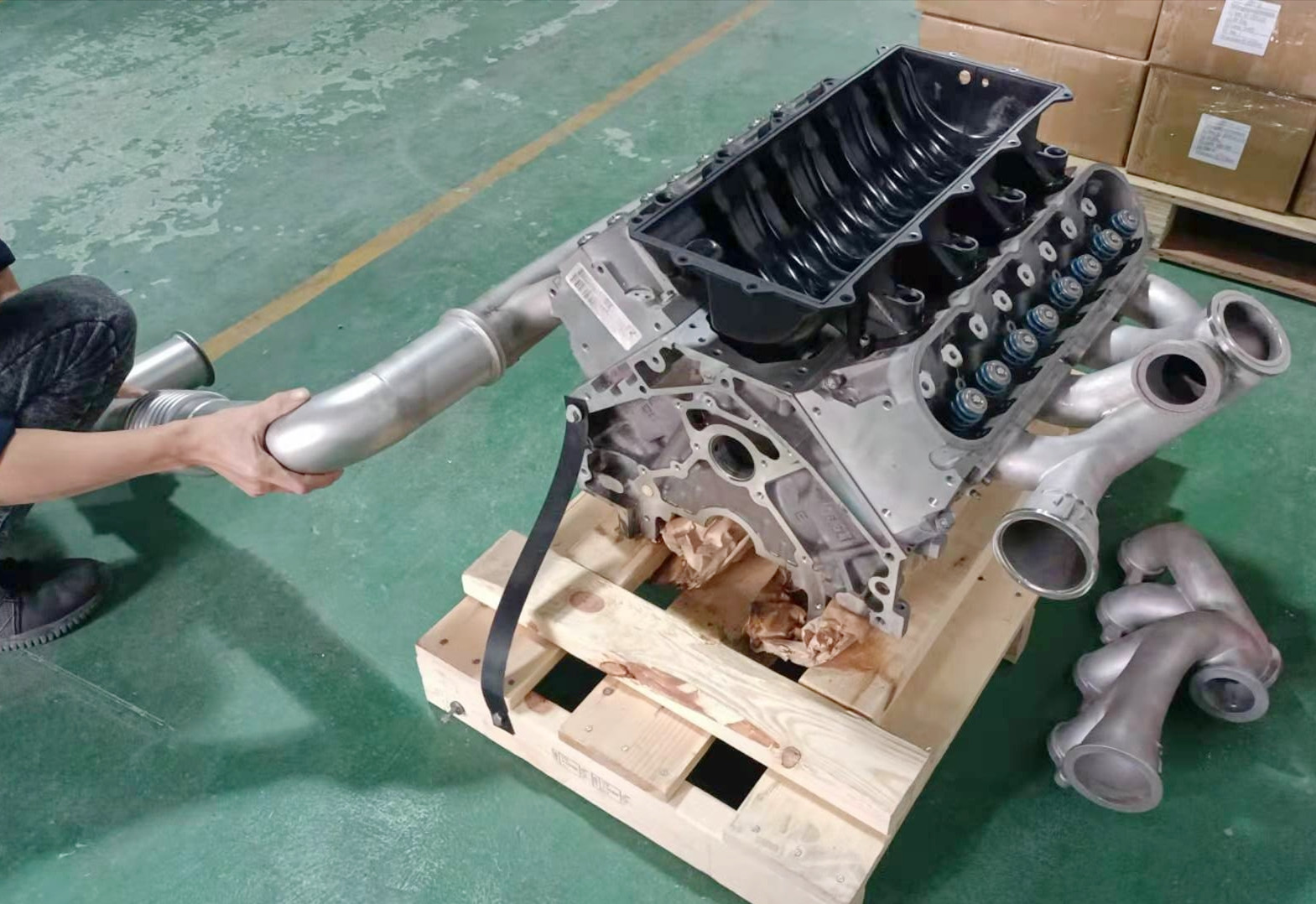

1. Xaqiiji in nooca qiiqa hawada sare uu ku habboon yahay gaariga.

2. Kor u qaad baabuurka si aad si fiican u gasho nidaamka qiiqa hoose. Ka saar mawjadaha qiiqa ee jira adoo isticmaalaya furaha.

3.Nadiifi xagga hoose ee nidaamka qiiqa. Ka saar noocyada qiiqa asalka ah, hoose ee nidaamka qiiqa waxaa laga yaabaa inuu leeyahay hadhaa ama miridhku, waxay u baahan yihiin in lagu nadiifiyo saabuunta ama qalabka burushka siliga.

4.Rakib nooc cusub oo qiiq ah. Dhig qaybta qiiqa cusub ee xidhiidhka jira oo ku xafid furaha. Waa in la ogaadaa in jihada mashiinnada qiiqa ah waa in fiiro gaar ah loo yeesho inta lagu jiro rakibidda si loo hubiyo in jihada hawadu ay sax tahay.

5.Ku xidh qaybta qiiqa ee nidaamka qiiqa hoose. Isticmaal furaha si aad ugu xidhidhiyaha qiiqa badan nidaamka qiiqa hoose oo aad hubiso in aanu jirin wax hawo ah oo ka soo daatay xidhiidhka.

6.Check rakibidda nidaamka qiiqa. Ka dib markii la rakibo waxay u baahan tahay in la hubiyo in nidaamka qiiqa uu yahay mid adag, haddii uu jiro qulqulo. Haddi la helo wax dillaacay, waxa ay u baahan tahay in dib loo hagaajiyo.

Guriga

Guriga