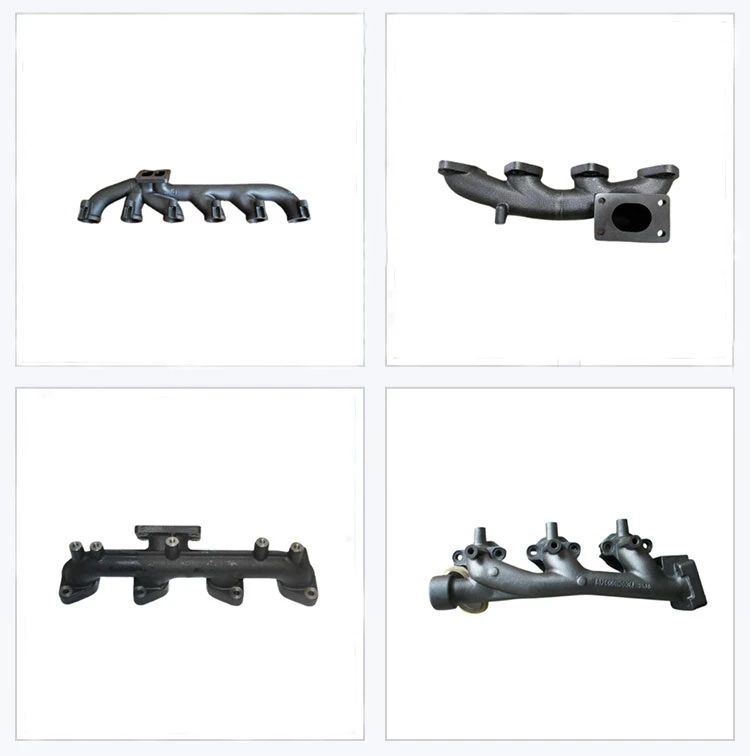

ISO9001 Umkhiqizi Custom Cast Iron Turbo Exhaust Manifold

incazelo2

incazelo2

①Ukumelana kahle ne-oxidation kumazinga okushisa aphezulu:Ukwengeza izakhi ze-alloying kokokusebenza:Ukusebenza kwe-anti-oxidation kwento emazingeni okushisa aphezulu kuthinta ngqo impilo yesevisi ye-exhaust eningi. Insimbi evamile yokusansimbi ngokusobala ayikwazi ukuhlangabezana nezidingo, ngakho-ke ukwengeza izakhi ze-alloy kundaba ukuze kuthuthukiswe ukumelana ne-oxidation ephezulu yezinga lokushisa.

②Isakhiwo esincane esizinzile:Into esetshenziswayo ye-matrix kungcono i-ferrite ezinzile noma isakhiwo se-austenite.

③Ithempelesha ephezulu nokumelana nokugqwala:I-Coefficient encane yokunwetshwa kwe-thermal kunenzuzo ekwehliseni ukuxineka okushisayo kanye nokuguqulwa kwama-nifold eesosi kanye nokuthuthukisa ukusebenza komkhiqizo nempilo yesevisi.

④Ukusebenza okuhle kwenqubo:Kunezinhlobo eziningi zezinto zensimbi ezikwazi ukumelana nokushisa nezingashisi kakhulu, kodwa ngenxa yomumo oyinkimbinkimbi we-exhaust eningi, okokusebenza okusetshenziselwa ukukhiqiza okuhlukahlukene kokukhipha umoya kufanele kube nokusebenza kahle.

1.Impahla:Insimbi yokuphonswa noma i-201ss insimbi engagqwali

2.Isevisi:Ukusakaza kwesihlabathi, ukusakaza kwamandla adonsela phansi, ukusakaza kwe-high pressure, ukusakaza okuphansi kwe-die cast kanye ne-CNC Machining casting.

3.Izisetshenziswa Zokusakaza:Umshini wokuphonsa isihlabathi;imishini yokukhipha igassing kanye namathuba okucwenga okokusebenza;5Sets CNC Machines;3 sets Milling machines; 3 amasethiImishini yokujika; Imishini engu-10 yokubhoboza neyompompi.

4.Indawo yokuhlola:i-spectrometer, umshini wokuhlola oqinile, umshini wokuhlola ubulukhuni,umbiko wobukhulu be-CMM.

5.Imishini eqondile: Ukuphenduka kwe-CNC, ukugaya, ukubhoboza, ukugaya, ukusika, ukubuyisela kabusha nokuhlanganisa.

6.Kuqediwe:Ukupholisha, ukuqhunyiswa kwesihlabathi, ukwelapha ukushisa, ukupenda, ukumbozwa ngempushana, ukugcotshwa kwe-anodizing,i-electroplating, i-Chrome plating, ukupholisha isibuko.

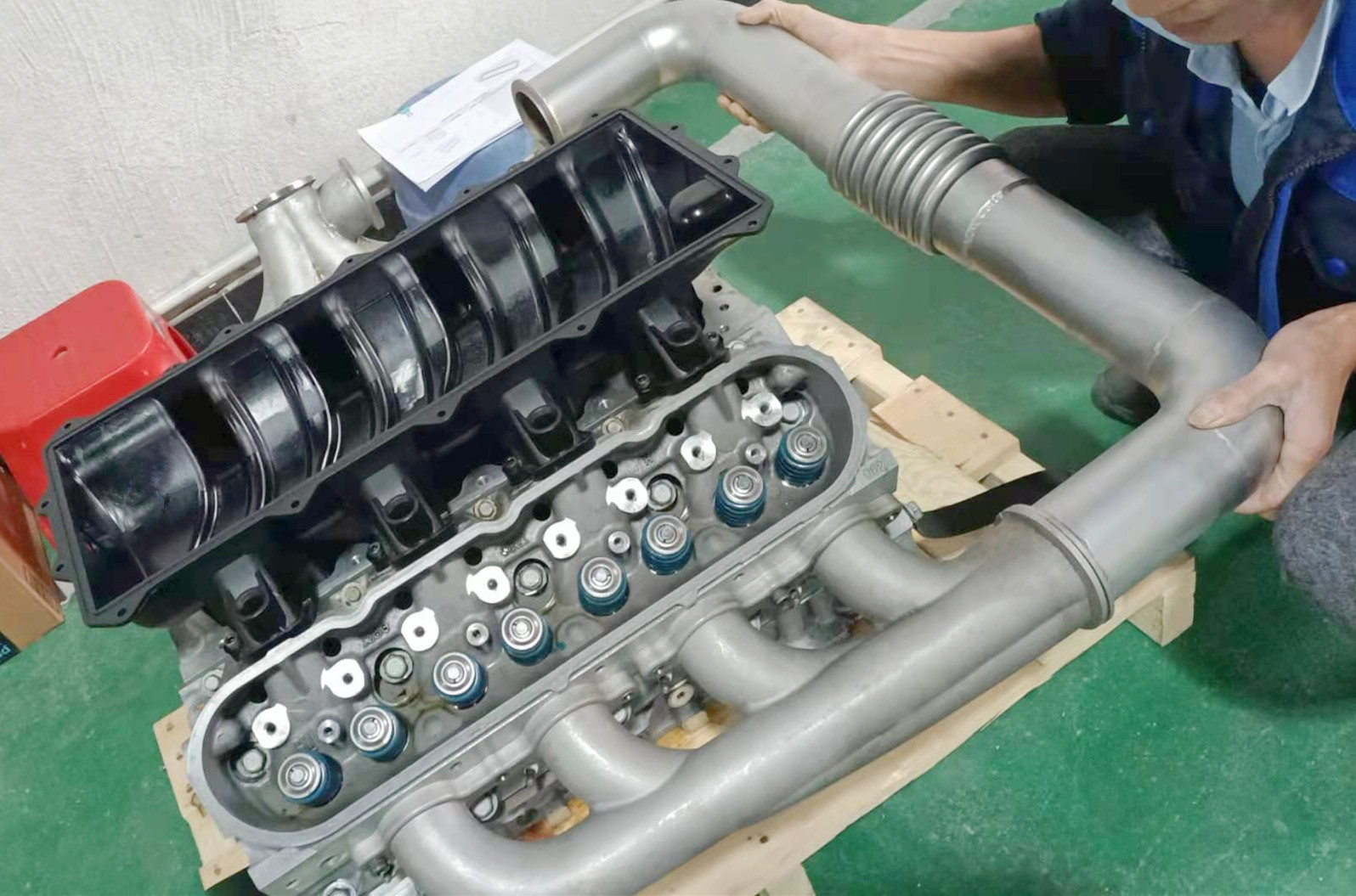

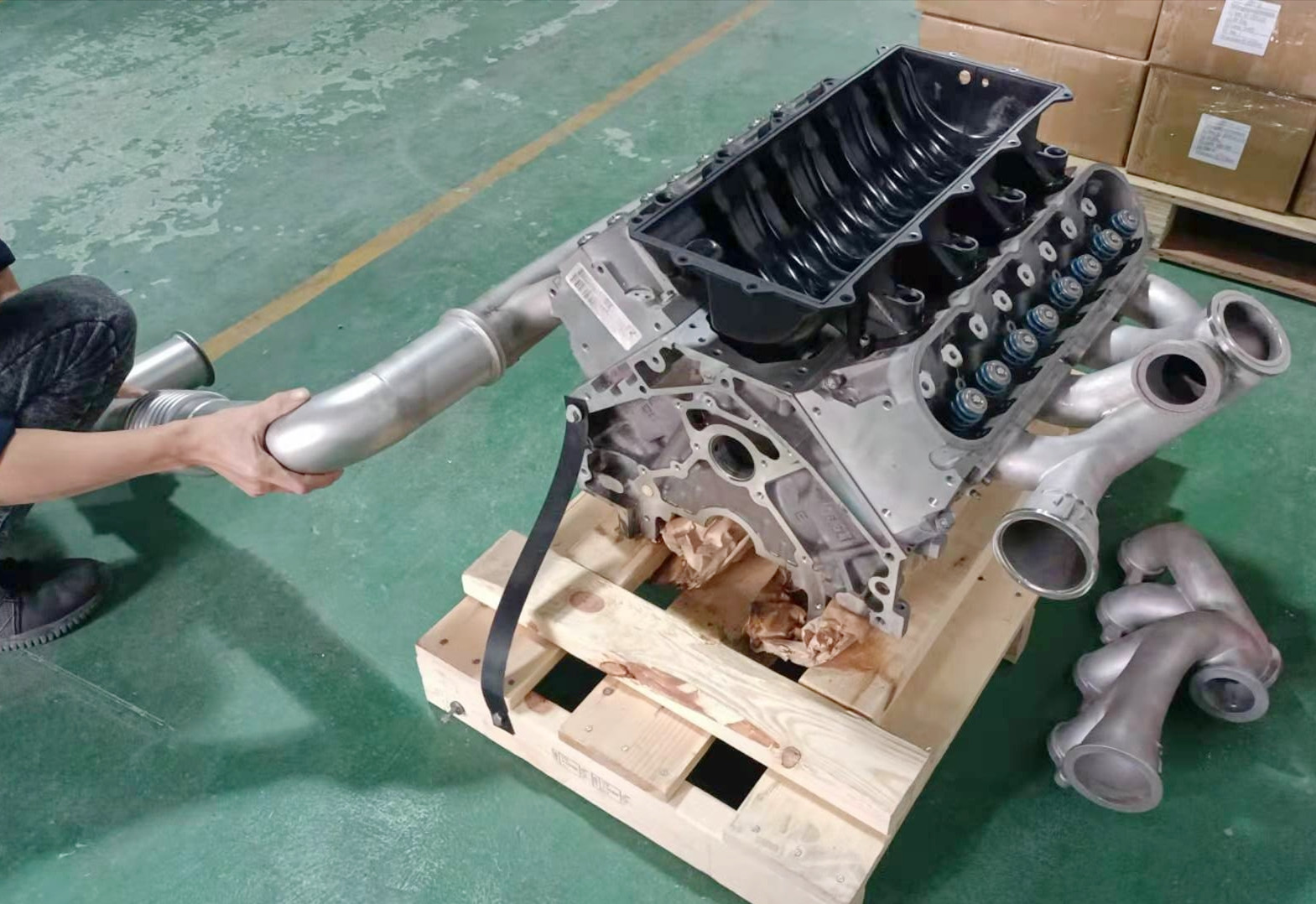

1. Qinisekisa ukuthi imodeli ye-exhaust eningi ifana nemoto.

2.Phakamisa imoto ukuze uthole ukufinyelela okungcono ohlelweni lwe-exhaust ephansi. Susa i-multifold exhaust ekhona usebenzisa isikrufu.

3.Hlanza phansi i-exhaust system. Susa i-multifold exhaust yasekuqaleni, indawo engaphansi yesistimu yokukhipha umoya ingase ibe nezinsalela noma ukugqwala, idinga ukuhlanzwa nge-detergent noma amathuluzi ebhulashi locingo.

4.Faka ama-nifold exhaust amasha. Beka i-multifold exhaust entsha ekuxhumekeni okukhona futhi uyivikele ngesikrufu. Kumele kuqashelwe ukuthi isiqondiso se-multifold exhaust kufanele sinakwe ngesikhathi sokufakwa ukuze kuqinisekiswe ukuthi isiqondiso sokuhamba komoya silungile.

5.Xhuma i-exhaust manifold ohlelweni oluphansi lokukhipha umoya. Sebenzisa isikrufu ukuxhuma i-exhaust manifold kusistimu yokukhipha umoya ephansi futhi uqiniseke ukuthi akukho kuvuza komoya ekuxhumekeni.

6.Hlola ukufakwa kwe-exhaust system. Ngemuva kokufakwa kudinga ukuhlola ukuthi isistimu yokukhipha umoya iqinile, ukuthi kukhona ukuvuza. Uma kuvuza kutholwa, kudinga ukulungiswa kusenesikhathi.

Ikhaya

Ikhaya