Manufaktur ISO9001 Custom Cast Iron Turbo Exhaust Manifold

katrangan2

katrangan2

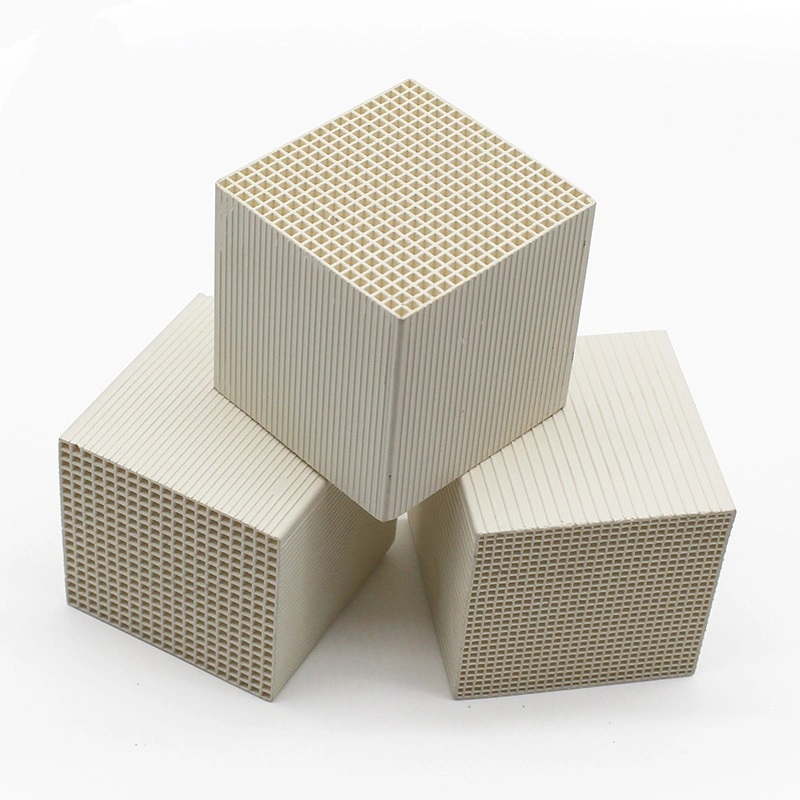

①Resistensi oksidasi sing apik ing suhu dhuwur: Nambahake unsur paduan menyang materi: Kinerja anti-oksidasi materi ing suhu dhuwur langsung mengaruhi umur layanan exhaust manifold. wesi cast biasa temenan ora bisa ketemu syarat, supaya nambah unsur alloy ing materi kanggo nambah resistance oksidasi suhu dhuwur saka materi.

②Mikrostruktur stabil:Bahan matriks luwih disenengi struktur ferit utawa austenit sing stabil.

③Temperatur dhuwur lan tahan korosi: Koefisien ekspansi termal cilik migunani kanggo nyuda stres termal lan deformasi manifold exhaust lan nambah kinerja produk lan umur layanan.

④Kinerja proses sing apik: Ana macem-macem jinis bahan logam sing tahan panas lan tahan suhu dhuwur, nanging amarga bentuke exhaust manifold sing rumit, bahan sing digunakake kanggo nggawe manifold knalpot kudu duwe kemampuan kerja sing apik.

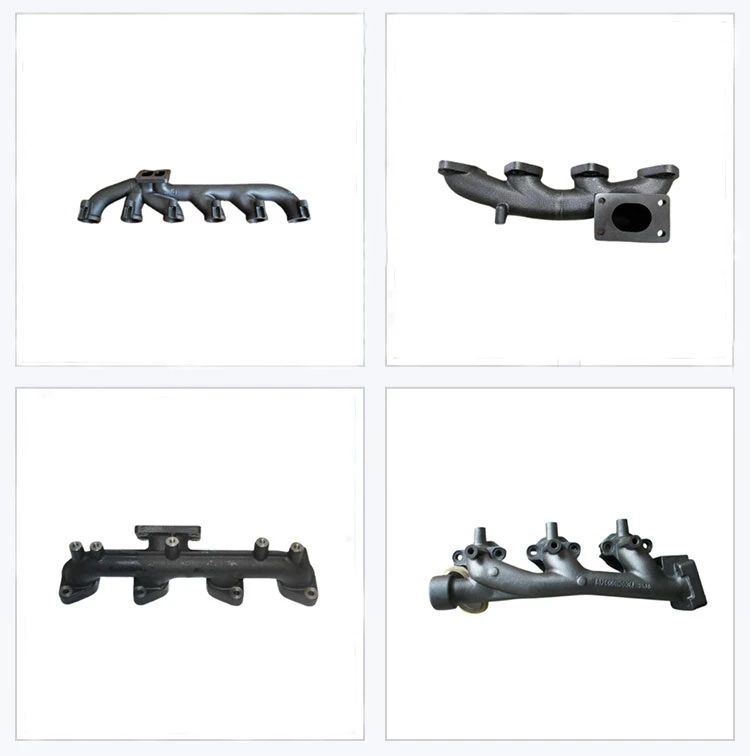

1.Material: wesi Cast utawa 201ss stainless steel

2.Service: Sand casting, Gravitasi casting, tekanan dhuwur die casting, tekanan rendah die casting lan CNC Machining casting.

3.Equipment saka Casting:Sand mesin casting;degassing peralatan lan kesempatan kanggo nyaring materi;5Sets CNC Machines;3 sets Mesin panggilingan; 3 set Mesin ngowahi; 10 set pengeboran lan mesin tunyuk.

4. Fasilitas pengujian: spektrometer, mesin uji tarik, mesin uji kekerasan, laporan dimensi CMM.

5.Precision machining: CNC ngowahi, panggilingan, ngebur, mecah, nglereni, reaming lan threading.

6. Rampung: Polishing, sand blasting, perawatan panas, lukisan, powder coating, anodizing, electroplating, Chrome plating, mirror polishing.

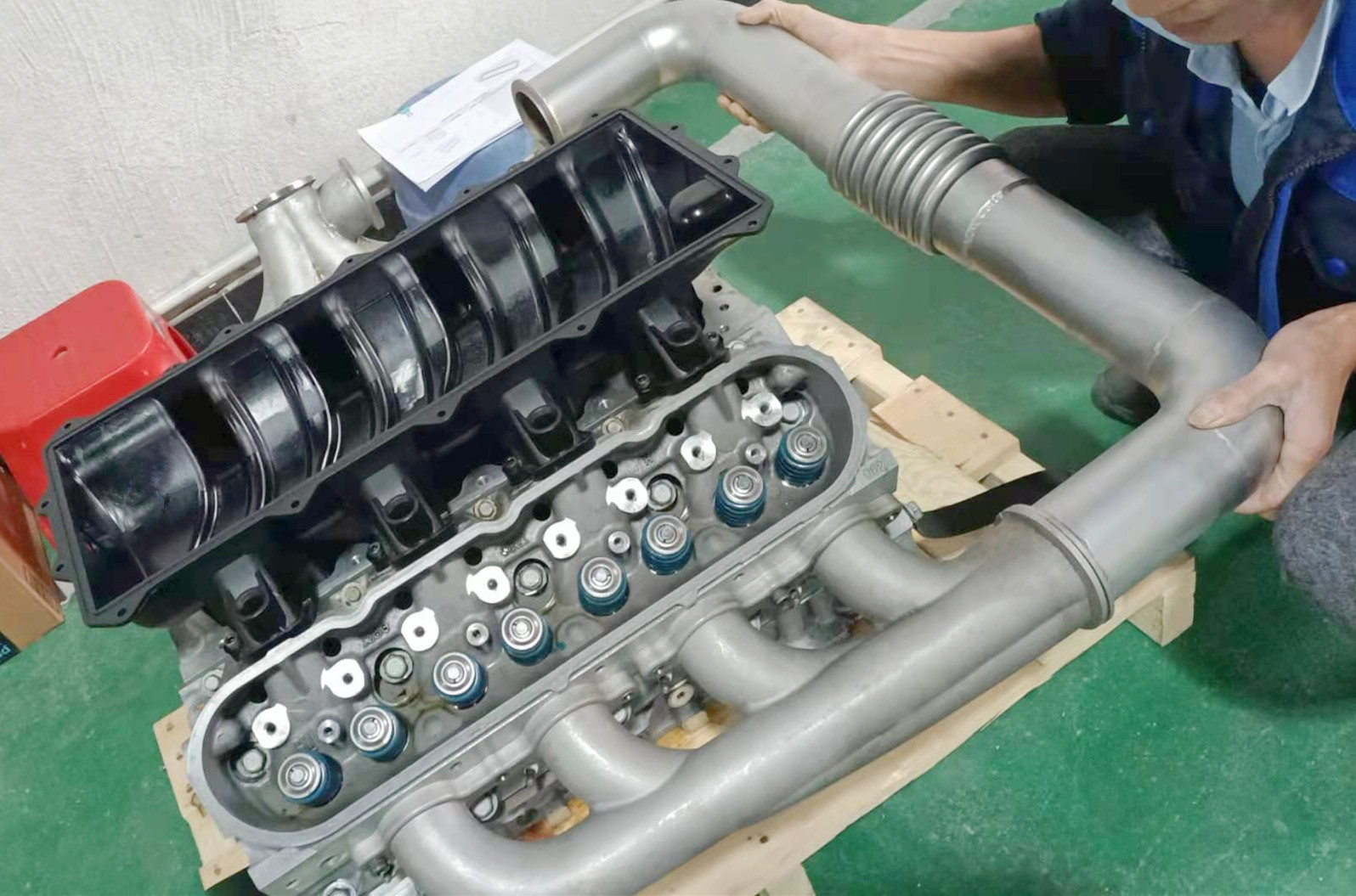

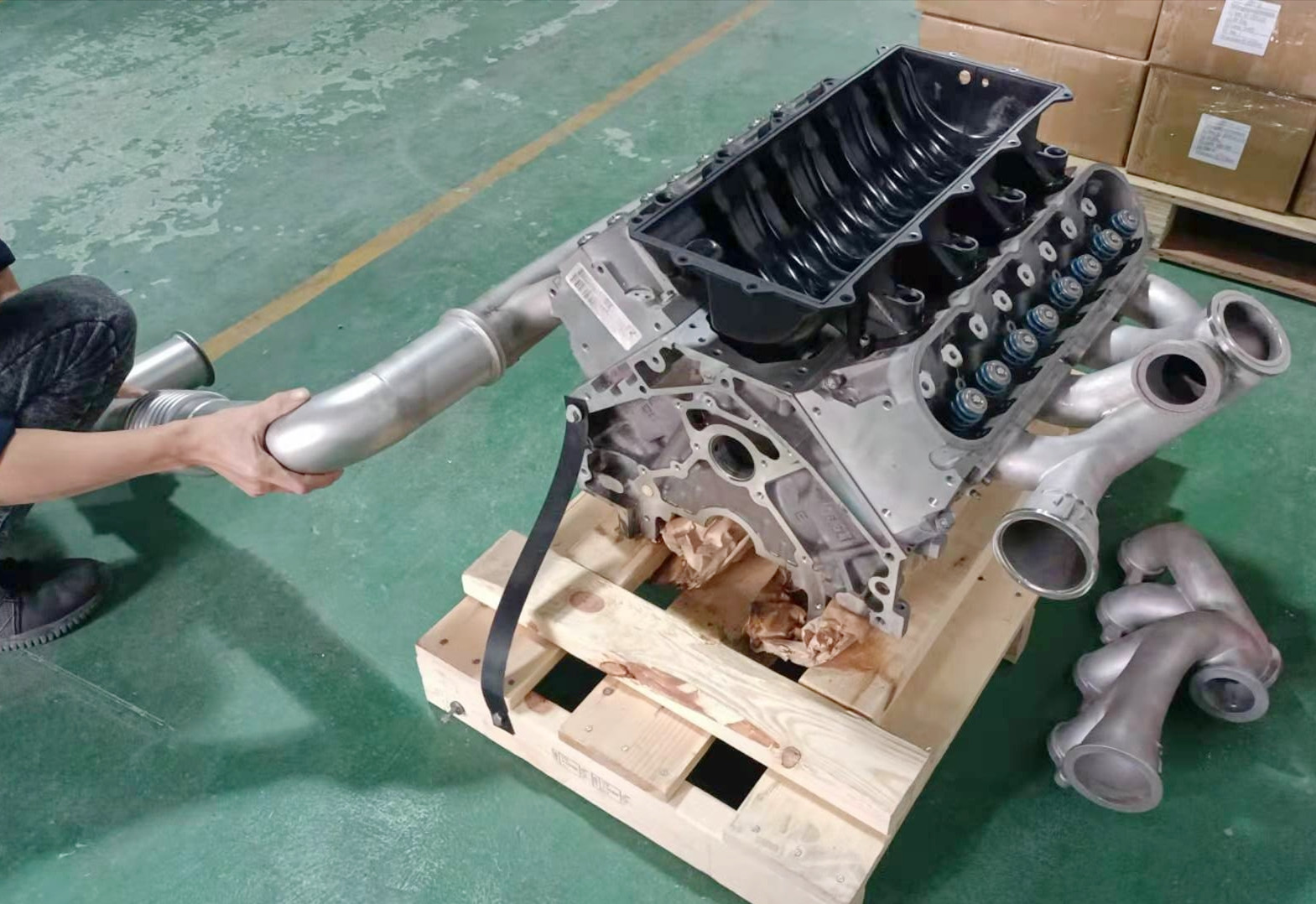

1.Verifikasi yen model manifold knalpot cocog karo kendaraan.

2. Angkat kendaraan kanggo entuk akses sing luwih apik menyang sistem knalpot ngisor. Copot manifold exhaust sing ana nggunakake kunci.

3. Ngresiki ngisor sistem exhaust. Copot manifold knalpot asli, sisih ngisor sistem knalpot bisa uga ana residu utawa karat, kudu di resiki nganggo deterjen utawa alat sikat kawat.

4. Pasang manifold knalpot anyar. Selehake manifold exhaust anyar ing sambungan sing wis ana lan aman nganggo kunci. Perlu dicathet yen arah manifold exhaust kudu digatekake sajrone instalasi kanggo mesthekake yen arah aliran udara bener.

5. Sambungake manifold exhaust menyang sistem exhaust ngisor. Gunakake kunci pas kanggo nyambungake manifold exhaust menyang sistem exhaust ngisor lan priksa manawa ora ana bocor udara ing sambungan kasebut.

6. Priksa instalasi sistem exhaust. Sawise instalasi perlu kanggo mriksa apa sistem exhaust ngalangi, apa ana bocor. Yen bocor ditemokake, kudu didandani ing wektu.

Ngarep

Ngarep