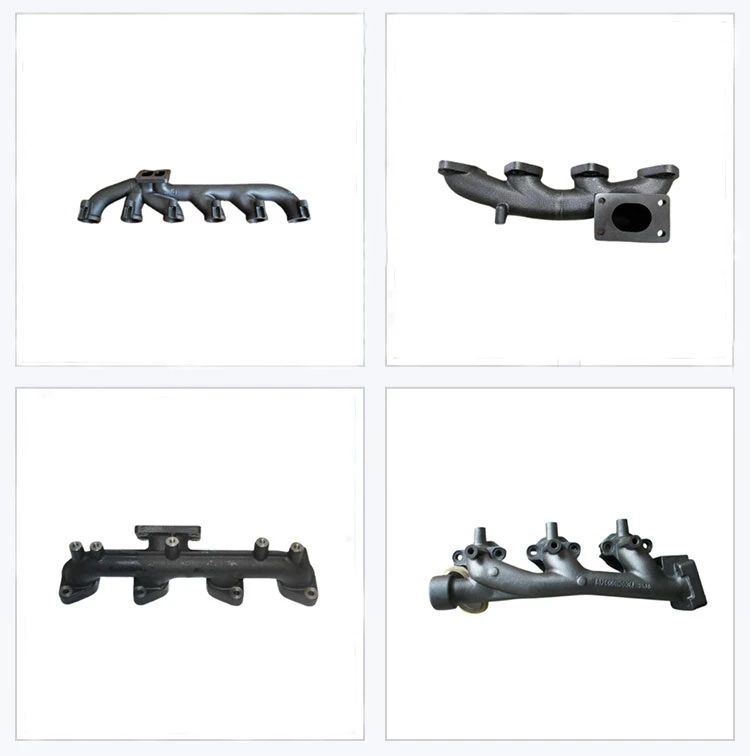

ISO9001 Moetsi Custom Cast Cast Iron Turbo Exhaust Manifold

tlhaloso2

tlhaloso2

①Ho hanyetsa oxidation e ntle mochesong o phahameng: Ho eketsa likarolo tsa alloying ho thepa: Ts'ebetso ea anti-oxidation ea thepa ka mocheso o phahameng e ama ka kotloloho bophelo ba ts'ebeletso ea mefuta e mengata ea ho tima. Tloaelehileng lahleloa tšepe ho hlakile hore a ke ke a kopana le ditlhoko, kahoo phaella ka ho re likarolo motsoako ka lintho tse bonahalang ho ntlafatsa phahameng-mocheso oxidation khanyetso ea lintho tse bonahalang tse.

②Stable microstructure: Thepa ea matrix ka ho khetheha ke sebopeho se tsitsitseng sa ferrite kapa austenite.

③Mocheso o phahameng le ho hanyetsa ha kutu: Mocheso o Monyenyane oa katoloso ea mocheso o molemo ho fokotsa khatello ea mocheso le ho senyeha ha mefuta e mengata ea mosi le ho ntlafatsa tshebetso ea sehlahisoa le bophelo ba tšebeletso.

④Ts'ebetso e ntle ea ts'ebetso: Ho na le mefuta e mengata ea lisebelisoa tsa tšepe tse sa keneleng mocheso le mocheso o phahameng, empa ka lebaka la sebopeho se rarahaneng sa mosi oa mosi, lisebelisoa tse sebelisoang ho etsa mosi o matla li tlameha ho sebetsa hantle.

1.Material: Lahlela tšepe kapa 201ss tšepe e sa hloekang

2.Tšebeletso: Ho lahla lehlabathe, ho lahla matla a khoheli, ho lahlela lefu la khatello e phahameng, ho lahlela lefu la khatello e tlase le CNC Machining casting.

3.Thepa ea ho Lahlela: Mochini oa ho lahla lehlabathe; lisebelisoa tsa ho senya le menyetla ea ho hloekisa thepa;5Sets CNC Machines;3 sete Milling machine; Mechini e 3 e fetolang; Mechini e 10 ea ho cheka le ho cheka.

4.Setsi sa tekolo: spectrometer, mochini oa teko oa tensile, mochini oa teko ea boima, tlaleho ea boholo ba CMM.

5.Precision machining:CNC ho fetola, ho sila, ho cheka, ho sila, ho itšeha, ho tsosolosa le ho kopanya.

6.Finished: polishing, lehlabathe blasting, kalafo mocheso, penta, phofo barbotage, anodizing, electroplating, Chrome plating, seipone bentša.

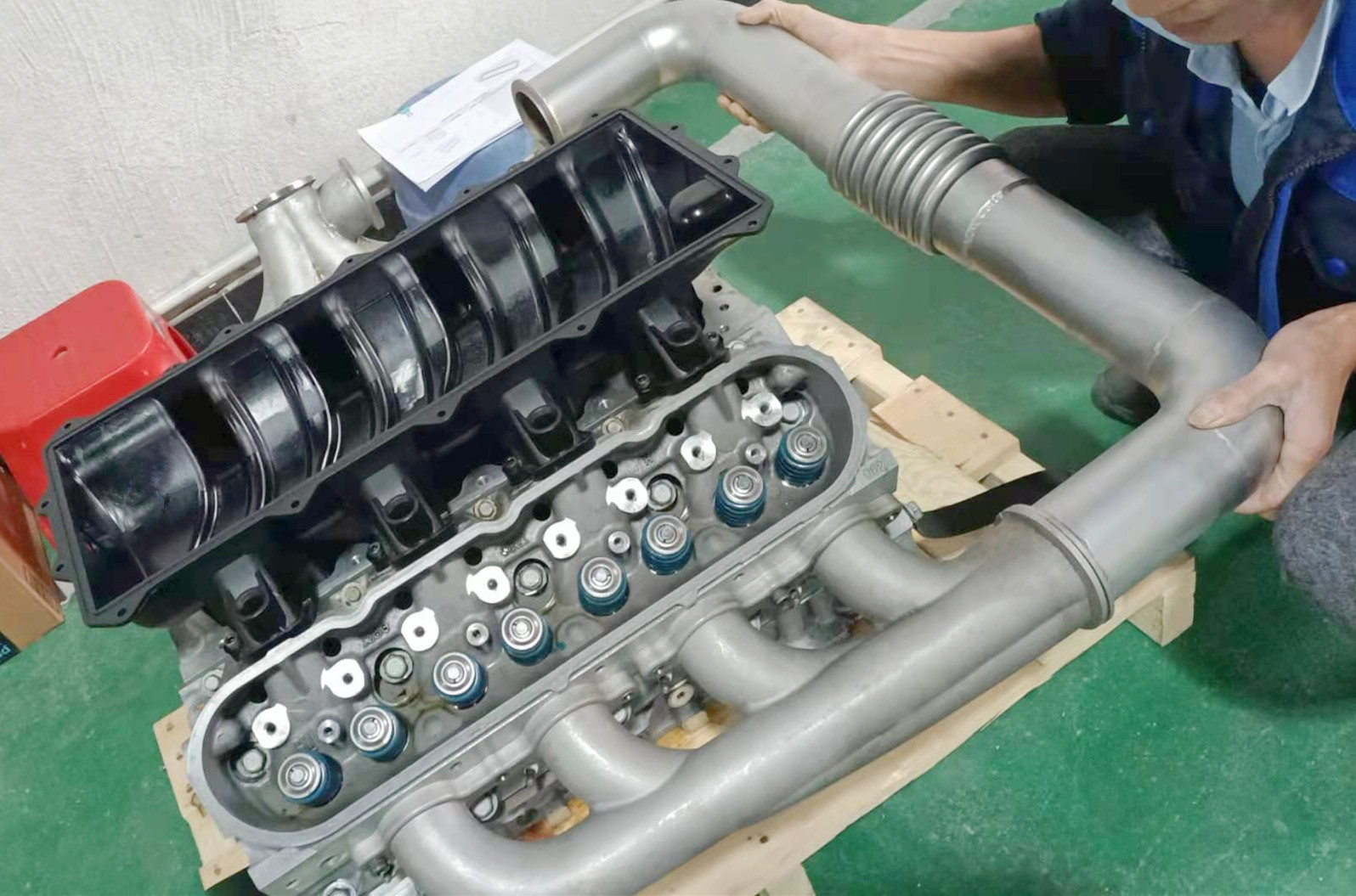

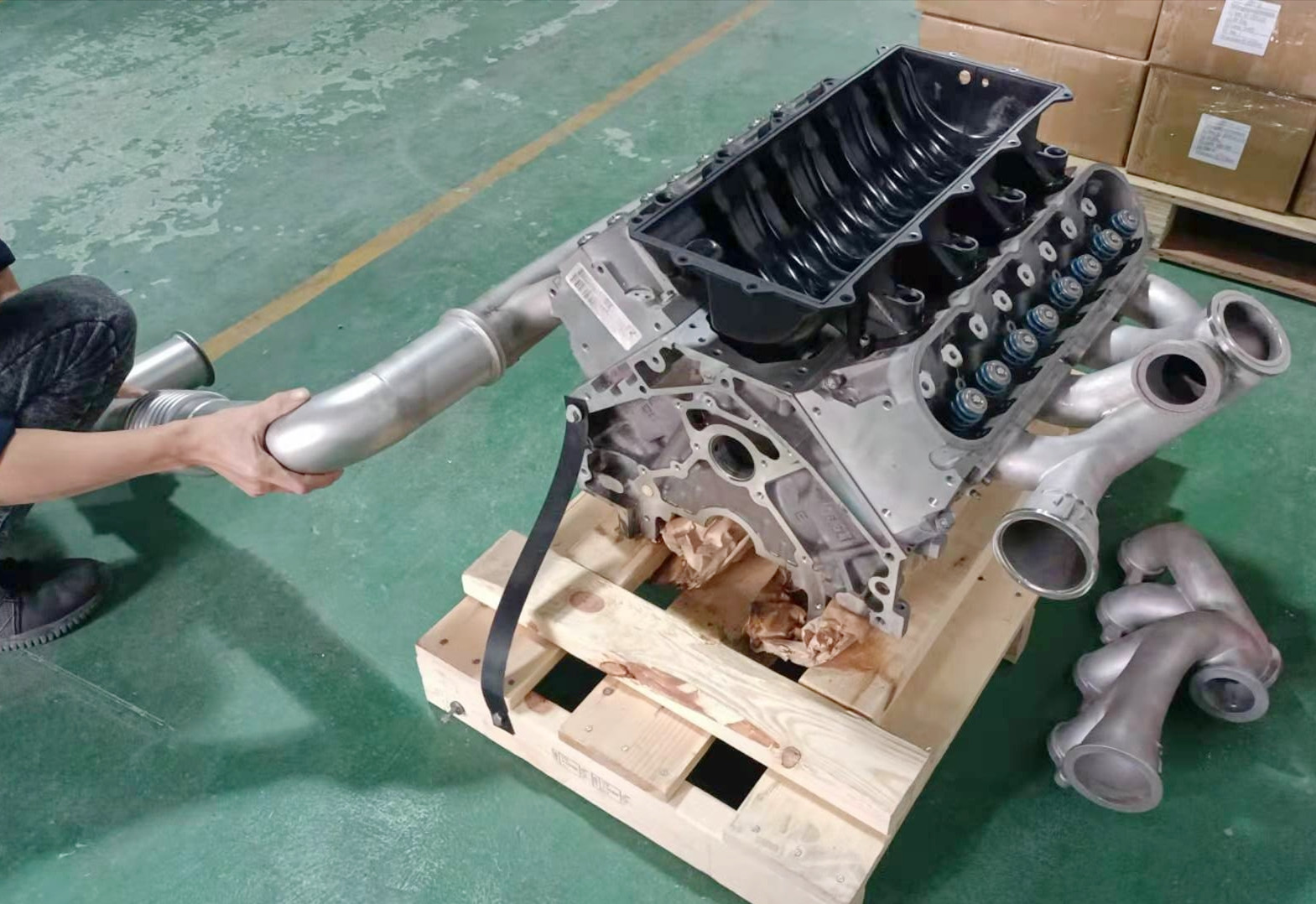

1. Netefatsa hore mofuta oa exhaust o tsamaisana le koloi.

2.Phahamisa koloi ho fumana mokhoa o motle oa ho fumana mokhoa o ka tlaase oa ho ntša metsi. Tlosa mokelikeli o teng oa ho qeta nako o sebelisa wrench.

3.Clean botlaaseng ba tsamaiso ea ho qeta nako. Tlosa mokelikeli oa pele oa ho qeta, karolo e ka tlaase ea tsamaiso ea ho qeta e ka 'na ea e-ba le masala kapa mafome, e hloka ho hloekisoa ka sesepa kapa lisebelisoa tsa terata.

4. Kenya lisebelisoa tse ncha tsa ho ntša metsi. Beha manifold e ncha ea exhaust holim'a khokahano e teng 'me u e sireletse ka wrench. Hoa lokela ho hlokomeloa hore tataiso ea manifold ea ho qeta e lokela ho lefshoa nakong ea ho kenya ho netefatsa hore tataiso ea moea e nepahetse.

5.Hokela mokelikeli o mongata oa ho tsoa ho sistimi e ka tlase. Sebelisa sekontiri ho hokela mochini o ntšang mokelikeli o mongata o ka tlase 'me u netefatse hore ha ho na moea o lutlang khokahanyong.

6.Check ho kenngoa ha tsamaiso ea ho qeta. Ka mor'a ho kenya, ho hlokahala ho hlahloba hore na tsamaiso ea ho qeta e tiile, hore na ho na le leakage. Haeba lets'oao le fumanoa, le hloka ho lokisoa ka nako.

Lehae

Lehae