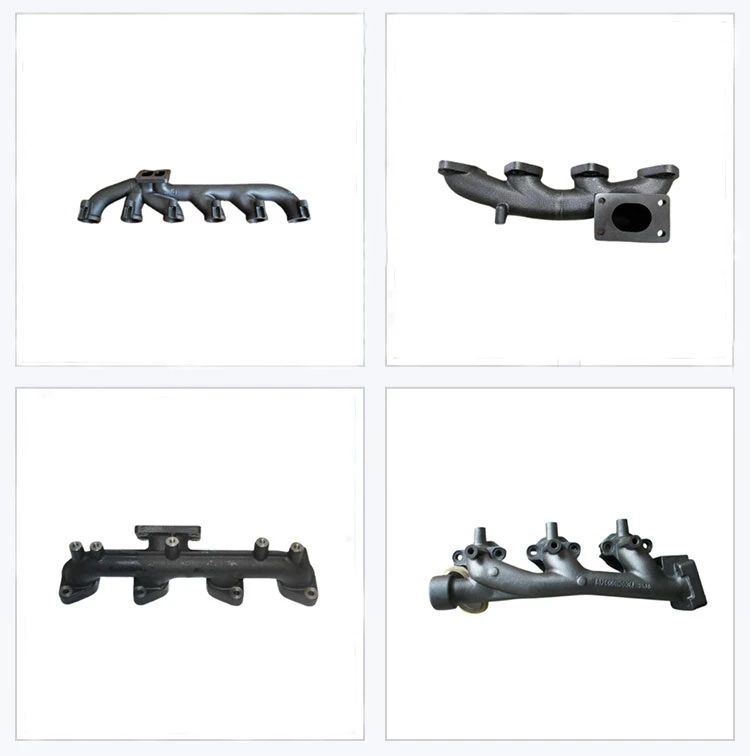

ISO9001 Manufacturer Custom Cast Iron Turbo Exhaust Manifold

inkcazelo2

inkcazelo2

①Ukumelana ne-oxidation elungileyo kwiqondo lobushushu obuphezulu:Ukongeza izinto ze-alloying kwimathiriyeli:Ukusebenza kwe-anti-oxidation yemathiriyeli kubushushu obuphezulu buchaphazela ngqo ubomi benkonzo yokukhupha okuninzi. Intsimbi yentsimbi eqhelekileyo ngokucacileyo ayinakukwazi ukuhlangabezana neemfuno, ngoko ke ukongeza izinto zengxubevange kwizinto eziphathekayo ukuphucula ubushushu obuphezulu be-oxidation yokumelana nezinto.

②I-microstructure ezinzileyo: Izinto zematrix zikhethwa ukuba ibe yi-ferrite ezinzileyo okanye isakhiwo se-austenite.

③Ubushushu obuphezulu kunye nokumelana nokukhula: I-Coefficient encinci yokwandiswa kwe-thermal iluncedo ekunciphiseni uxinzelelo lwe-thermal kunye nokuguqulwa kwezinto ezininzi zokukhupha kunye nokuphucula ukusebenza kwemveliso kunye nobomi benkonzo.

④Ukusebenza kakuhle kwenkqubo: Zininzi iindidi zezixhobo zentsimbi ezikwaziyo ukumelana nobushushu kunye nobushushu obuphezulu, kodwa ngenxa yobume obuntsonkothileyo bombhobho wokukhupha izinto ezininzi, izinto ezisetyenziselwa ukwenza umbhobho wokukhupha izinto ezininzi kufuneka zisebenze kakuhle.

1.Izinto eziphathekayo:Intsimbi yokuphosa okanye i-201ss intsimbi engenasici

2.Inkonzo:Sand cast, Gravity casting, high pressure die casting, low pressure die casting and CNC Machining casting.

3.Izixhobo zokuSasa:Umatshini wokugalela isanti;isixhobo sokususa igassing kunye namathuba okucokisa imathiriyeli;5Iiseti zoomatshini be-CNC;iiseti ezi-3 zoomatshini bokugaya; Iiseti ezi-3 zokutshintsha oomatshini; 10 iiseti drill kunye noomatshini impompo.

I-4.Indawo yokuvavanya:i-spectrometer, umatshini wokuvavanya i-tensile, umatshini wokuvavanya ubulukhuni,ingxelo yomlinganiselo weCMM.

I-5.Umatshini ochanekileyo: Ukuguqula i-CNC, ukugaya, ukugaya, ukugaya, ukusika, ukubuyisela kwakhona kunye nentambo.

6.Kugqityiwe: Ukupholisha, ukuqhushumba kwesanti, unyango lobushushu, ukupeyinta, ukugquma umgubo, i-anodizing, i-electroplating, i-Chrome plating, ukugulisa isipili.

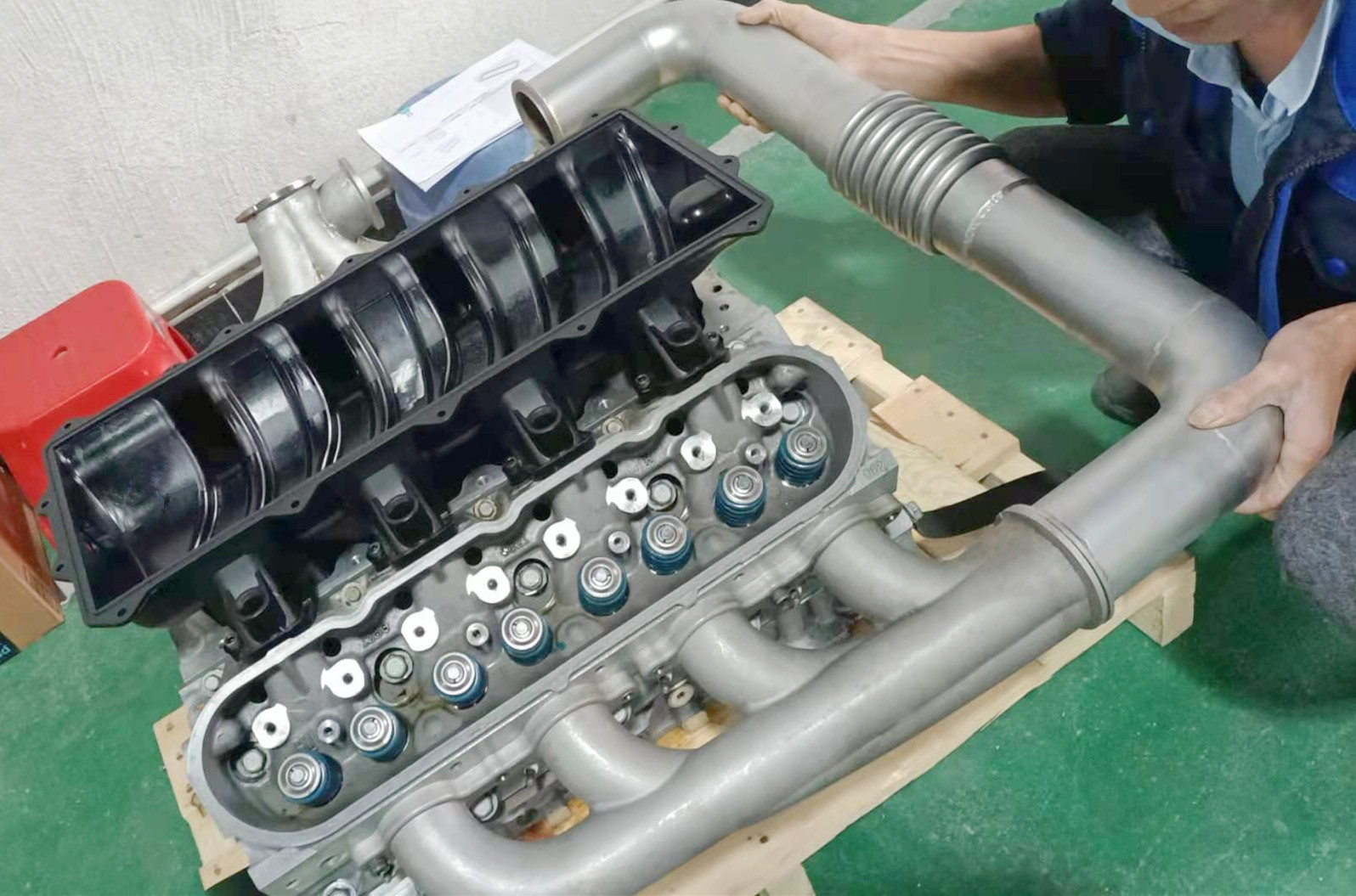

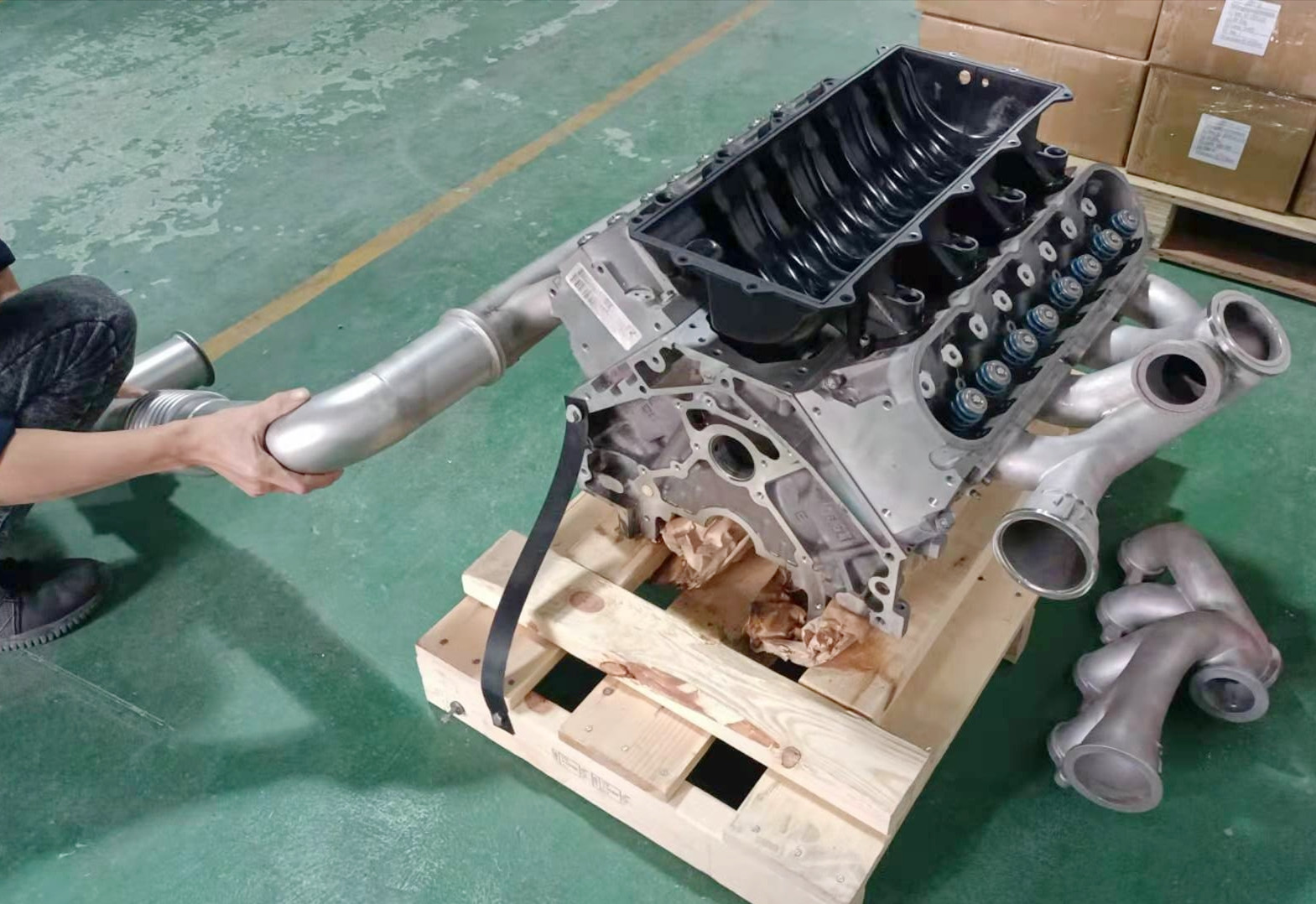

1.Qinisekisa ukuba i-exhaust manifold model ihambelana nesithuthi.

2.Phakamisa isithuthi ukuze ufumane ukufikelela okungcono kwindlela yokukhupha ephantsi. Susa umbhobho okhoyo wokukhupha usebenzisa isitshixo.

3.Coca umzantsi wenkqubo yokukhupha. Susa i-original exhaust manifold, i-bottom ye-exhaust system ingaba ne-residu okanye i-rust, idinga ukucocwa nge-detergent okanye izixhobo zebrashi yocingo.

4.Fakela i-exhaust eninzi. Beka i-exoust manifold entsha kumdibaniso okhoyo kwaye uyikhusele ngesitshixo. Kufuneka kuqatshelwe ukuba isalathiso se-exhaust manifold kufuneka sinikwe ingqwalasela ngexesha lofakelo ukuqinisekisa ukuba ulwalathiso lokuhamba komoya luchanekile.

5.Qhagamshela i-exhaust manifold kwi-system exhaust system. Sebenzisa isitshixo ukudibanisa i-exhaust manifold kwi-exhaust system esezantsi kwaye uqinisekise ukuba akukho kuvuza komoya kumdibaniso.

6.Hlola ukufakwa kwenkqubo yokukhupha. Emva kokufakela kufuneka kukhangelwe ukuba ngaba inkqubo yokukhupha iqinile, nokuba kukho ukuvuza. Ukuba kuvuza kufunyenwe, kufuneka kulungiswe kwangethuba.

Ekhaya

Ekhaya